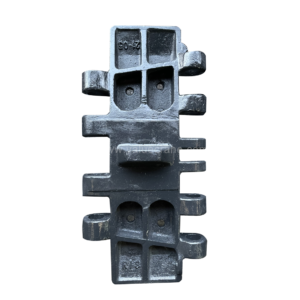

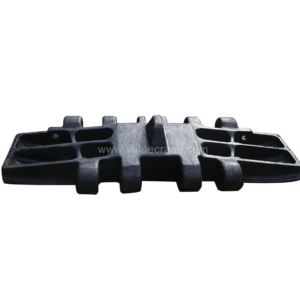

Ensuring proper maintenance for the various types of Liebherr crawler crane track shoes can be a daunting task. However, with the guidance of Value Crane, you can learn effective and practical maintenance techniques to guarantee smooth crane operations.

maintenance frequency of liebherr crawler crane track shoes

The maintenance frequency for Liebherr crawler crane track shoes depends on several factors and can vary based on the track shoes type and operating conditions. In general, maintenance should be performed every 250 to 500 operating hours.

Special Types liebherr Track shoes Maintenance

There are some types of Liebherr track shoes may require more frequent maintenance due to their design or material composition.

- Rubberized Liebherr Track pads: Liebherr track shoes with rubberized pads or inserts tend to wear more quickly compared to steel track shoes. The rubberized components are susceptible to abrasion, tearing, and degradation over time.

- High-Load Liebherr Track Shoes: Liebherr track pads designed for heavy-duty applications, capable of accommodating larger loads, may experience increased stress and wear.Regular inspections, bolt tightening, and track tension adjustments are crucial to maintain their integrity and prevent issues that may arise from the higher load capacities.

- Interlocking Liebherr Track Pads: Interlocking track shoes consist of multiple individual sections that connect together. These sections may experience increased movement and potential for misalignment during crane operation.

Six steps maintain liebherr crawler crane track shoes

Three basic steps

Inspection

- Conduct visual inspections of the Liebherr track pads before and after each operation.

- Look for signs of wear, damage, cracks, deformations, loose bolts, or misalignment.

- Inspect the track shoe pads and grousers for excessive wear or damage.

- Use water, brushes, and non-abrasive cleaning tools to remove dirt, mud, and debris from the Liebherr track shoes.

- Pay attention to hard-to-reach areas and ensure thorough cleaning to prevent abrasive wear.

Cleaning

Lubrication

- Apply the recommended lubricant to the track shoe components, including pins, bushings, and bolts.

- Follow the manufacturer’s guidelines for the appropriate lubrication intervals and the type of lubricant to use.

- Ensure even distribution of lubricant to minimize friction and wear.

Three special steps

You don’t have to follow these three steps for every maintenance session, unless you feel the operation of the crane is not smooth.

Bolt Tightening

Use a torque wrench to tighten them to the specified torque values provided by the manufacturer.

Track Tension

Monitor and adjust the track tension as per the manufacturer’s recommendations.

Track Alignment

Use precision measuring tools such as laser alignment equipment to assess the track alignment accurately.

Different maintenance Step With Different model types

Maintenance procedures for different types of Liebherr crawler crane track shoes may vary slightly. Value Crane, a trusted Liebherr track pads supplier, offers a diverse range of options, including those for models such as the Liebherr LR1600, Liebherr LR1280, and Liebherr HS885HD, among others. With our extensive experience as a supplier, we possess comprehensive knowledge of the specific maintenance requirements for each type of track shoe.

Whether you have inquiries or need assistance with your Liebherr track shoes, Value Crane is well-equipped to provide accurate and reliable information. Contact us today to benefit from their expertise and friendly service.